Optimizing Indirect Functions: The Hidden Key to Manufacturing Efficiency

When discussing manufacturing efficiency, much of the attention tends to focus on direct production areas such as, assembly lines, machine uptime and cycle times. But there is a less visible, often underestimated component that significantly influences productivity, cost, and quality: indirect areas. During periods of market stagnation, adjusting direct capacities is relatively easier, whereas indirect areas tend to be more rigid and challenging to modify.

These indirect areas include functions such as maintenance, logistics, quality assurance, planning, tooling, IT support, and various other administrative roles. Optimizing these areas doesn’t always grab headlines, but it’s a powerful lever for improving performance — especially in highly competitive environments.

Optimizing indirect areas is no longer about eliminating inefficiencies. In today’s manufacturing landscape, it’s about survival, agility, and sometimes, making bold organizational decisions that disrupt long-standing structures.

Why Optimizing Indirect Areas Matters

While indirect functions don’t directly transform raw materials into products, they shape the flow, precision, and stability of those transformations. Optimization delivers:

- Faster response to disruptions (e.g., proactive maintenance, agile planning).

- Reduced overhead costs.

- Higher product quality via efficient quality loops.

- Better use of digital systems and automation.

- Improved cross-functional decision-making.

Yet despite their importance, indirect areas are rarely sized, designed, or monitored with the same discipline as direct labor. It’s important to note that optimizing indirect areas is not as straightforward as optimizing direct areas.

The Volume Illusion: Non-Linear Challenges in Indirect Manufacturing Areas

One of the most complex challenges in manufacturing is that indirect resources cannot simply scale up or down with volume. For example:

- A 30 percent increase in volume may only require a 10 percent increase in maintenance staff — or none, if uptime is managed better.

- Conversely, a 10 percent product complexity increase may drive a 50 percent surge in planning or quality effort.

This non-linearity often results in sites being either overstaffed due to past volume peaks or critically constrained during complexity spikes.

The complexity of indirect areas increases with:

- Invisible Inefficiencies: Unlike takt time or scrap rate, inefficiencies in indirect areas are harder to detect. Time wasted in meetings, poor communication flows, or redundant data entry often go unnoticed and are not captured in KPIs.

- Organizational Resistance: Indirect functions often span across multiple departments. Optimizing them may require cross-functional alignment, role redefinition, or even a cultural change — all of which are harder to implement than tuning a production cell.

- Technology Mismatch: Digital tools offer promise, but poorly integrated systems or user resistance can create friction rather than efficiency. Automation in indirect areas (e.g., automated scheduling, maintenance analytics) has to be tailored — not just adopted.

Rethinking Indirect Areas: A Two-Step Optimization Framework

When optimizing indirect areas, the traditional instinct is to enhance productivity by improving processes with lean measures — optimize roles, automate tasks, or add dashboards. But what if we flipped the question entirely?

Instead of asking “How do we improve this function?”, ask: “Do we even need this function at all?”

To be able to answer this question we are recommending an archetype analysis to a manufacturing site to understand the necessity of certain functions. Not every indirect role or department is still justified in today’s production reality — especially as digital tools, integrated operations, and cross-functional teams replace traditional silos.

Step 1: Archetype Analysis – Challenge the Function Itself

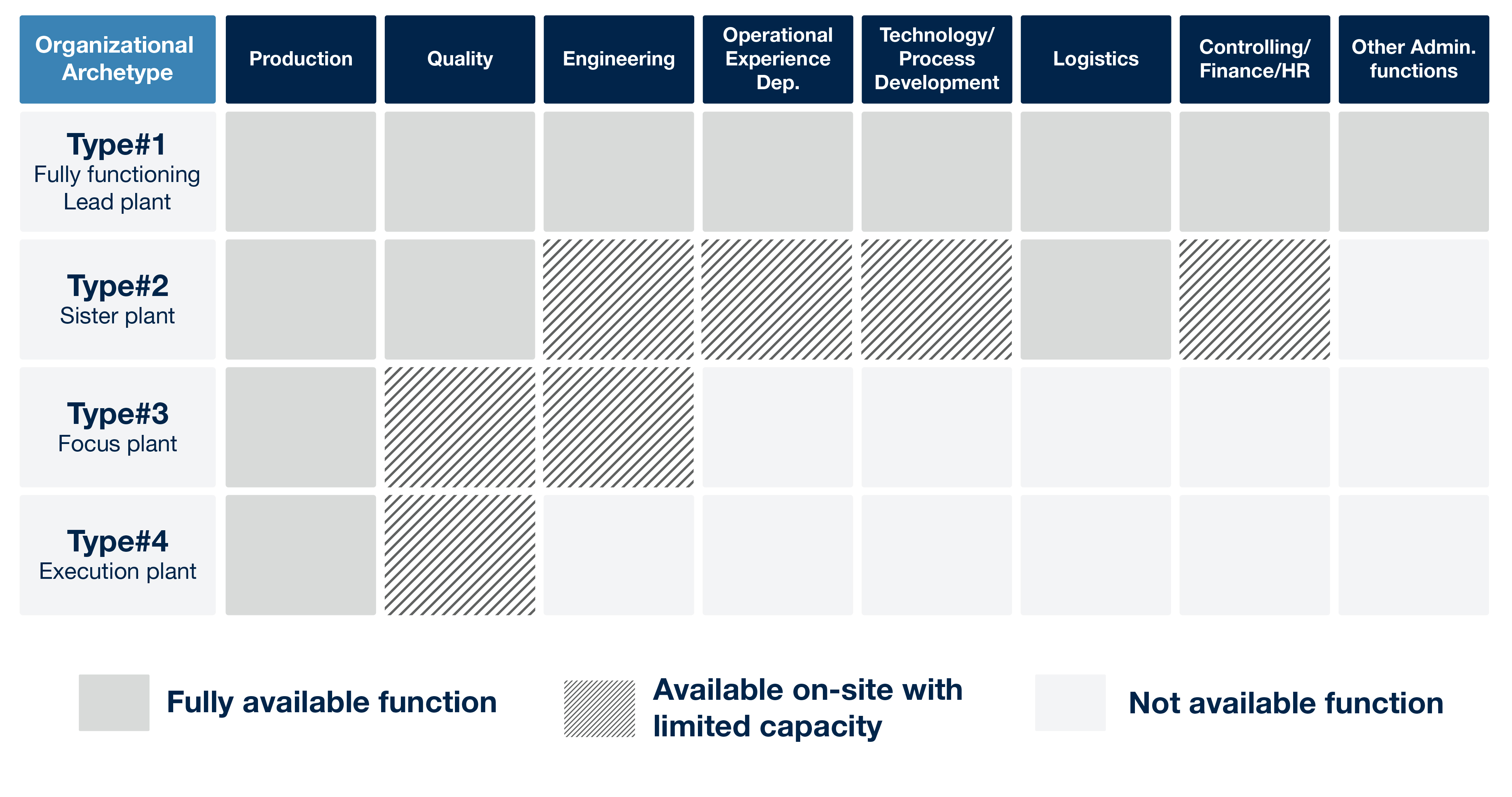

This analysis focuses on understanding the role of a specific manufacturing site.

The availability of different functions can be determined based on the role of the site.

For example, is this production site focusing on only execution of a production plan and are these products also manufactured on a different site. Then, this site is potentially an execution site and needs to fulfill these tasks. Under these circumstances this manufacturing site does not require full scale overhead functions – e.g.,quality, product engineering or technology development. These overhead functions can potentially be handled by central functions or by a larger manufacturing site which can act as a Hub site – a different archetype.

Example demonstrating different availability of capacities on a site according to the archetype:

In the example above, the lead 'hub' plant encompasses all related functions. Depending on its classification under a different archetype, one plant may eliminate or streamline these functions.

Before removing a function, one should evaluate whether the function should continue to exist as a standalone entity. Potential questions to answer:

- Does this function create value, or does it compensate for broken upstream processes?

- Is this function a product of historical complexity no longer relevant today?

- Could its responsibilities be redistributed and better executed elsewhere — closer to the process, or into digital systems?

It is important to emphasize that during a transformation, headcount adjustments are generally easier when a function is completely removed from a plant, rather than optimizing a specific function and reducing headcount as a result.

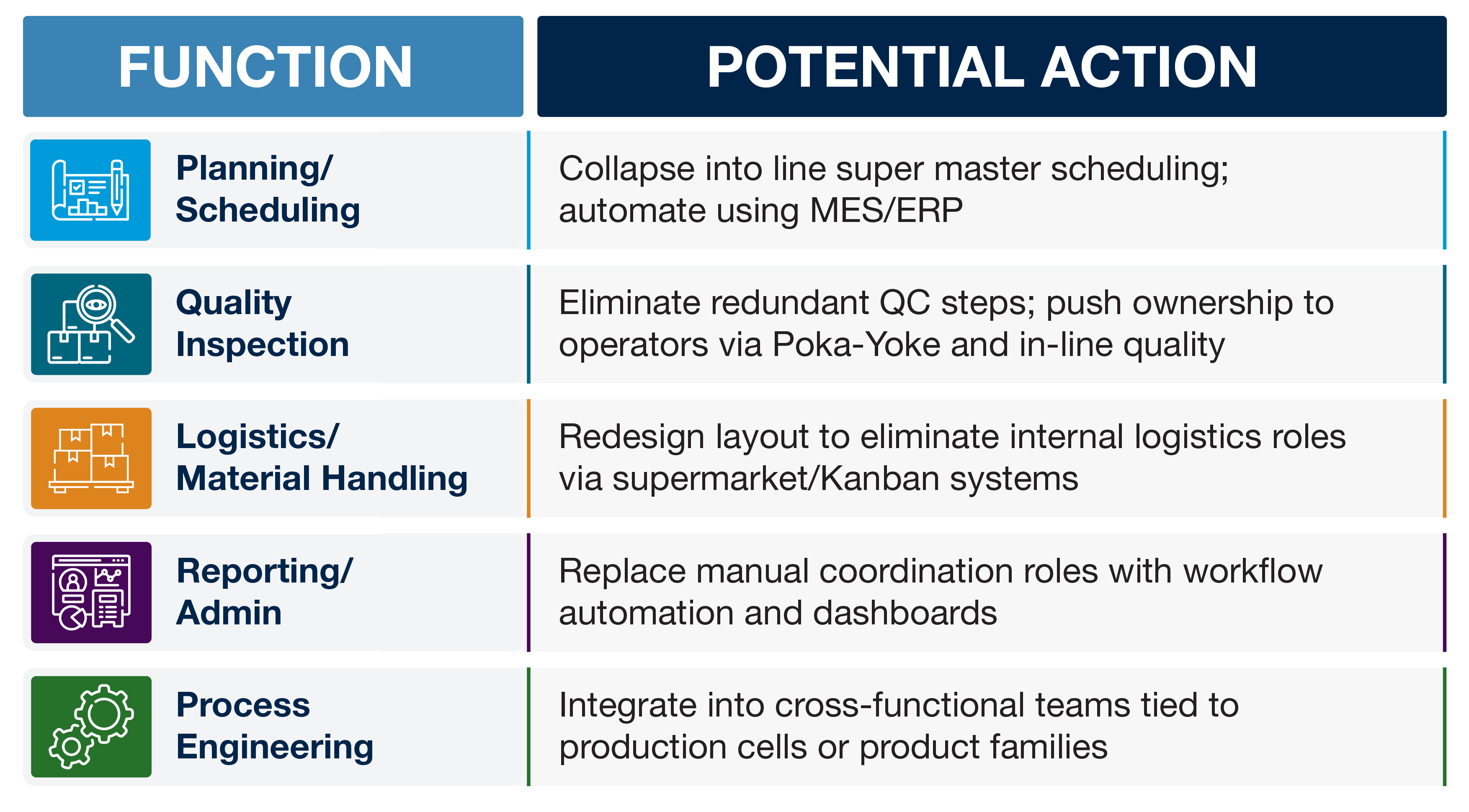

Step 2: Targeting Improvement Levers

The primary objective of the second step is rightsizing. Following the archetype analysis in step one, if it is determined that a specific function should remain, further optimization and rightsizing are necessary. These activities adopt a more traditional approach, beginning with an analysis through process mapping and data evaluation, followed by in-depth improvement workshops: Process Mapping - Function Analysis – Time Use Mapping.

Capture the existing processes within a department/function and consolidate the processes under main and sub processes. During this activity, aim to consolidate processes into a manageable number.

Map the current time allocation of team members against these processes.

This will highlight areas with:

- Overlapping Responsibilities: This will clearly reveal instances where different departments are performing the same tasks, leading to overlapping responsibilities. For example: Customer claim management or purchasing indirect areas.

- Multiple manual reporting.

- High amount of other non-value adding activities, such as alignment rounds, additional non-required testing, KPI tracking etc.

Deep Dive Workshops and Improvements

- Value Stream Mapping: Achieve further improvements with value stream mapping to cover areas beyond production end to end – also leverage swimlane methodology.

- Activity Based Role Definition: Analyze where time and cost are consumed in indirect areas — not just headcount, but activity-level granularity. This reveals high-effort, low-value tasks ripe for streamlining.

- Standardized Work: Define clear roles, responsibilities, and escalation paths in support functions. Use standard work and digital workflows to reduce variance. Appy the RACI methodology.

- Digital: Well-designed ERP, MES (Enterprise Resource Planning and Manufacturing Execution Systems), and data analytics tools can cut reporting and planning time dramatically. But success depends on user training and system integration.

- Cross-functional KPIs: Align incentives, if production KPIs are driving decisions but planning or logistics are left out, inefficiencies will persist. Shared KPIs improve coordination (e.g., Delivery performance, inventory level, etc.).

Case Study:

Plant X: Uncovering the Indirect Iceberg in Manufacturing Optimization

What We Found – Automotive supplier Tier1

- Planning Function Duplication:

Multiple planners were duplicating efforts due to poor ERP use and fragmented responsibility for BOMI, routing, and scheduling. Some roles were primarily focused on repetitive tasks, such as copying and pasting data between Excel and SAP. - Quality Teams Compensating for Broken Processes:

A large portion of QA resources were “policing” — performing redundant inspections because of trust gaps in upstream processes. - Logistics Loops Inefficiency:

Overstaffed because of fragmented material flow design — excessive internal movements due to layout and lack of PFEP (Plan for Every Part). - Maintenance as Firefighters, Not Engineers:

70 percent of maintenance time was reactive. Preventive Maintenance (PM) programs were in place but were poorly executed due to a lack of clear ownership and accountability.

Based on the archetype analysis, the site was classified as a Non-Hub site due to its role in executing production plans for modular components, as a result of that the planning responsibilities are transferred to the hub site. The whole planning department is removed from the organization.

With further process and function analysis, the quality and maintenance departments have been streamlined. This is done through operator self control as well as introduction of a preventive maintenance program to reduce the reactive capacity allocation.

Results and Insights

These changes not only reduced inefficiencies but also improved overall site performance. By addressing the root causes of indirect inefficiencies, Plant X was able to:

- Eliminate redundant roles and tasks

- Enhance cross-functional collaboration

- Build a more agile and efficient operation

This case study highlights the importance of challenging traditional structures and leveraging archetype analysis to unlock hidden potential in manufacturing sites.

Conclusion

In optimizing indirect areas, incremental change has its limits. Radical simplification — including the elimination or absorption of entire functions — can deliver far greater value than attempting to perfect an outdated structure.

A factory’s competitiveness doesn’t depend on the number of support staff it has. It depends on how few it needs, achieved through well-designed processes, systems, and ownership that prevent complexity from accumulating in operations.

By adopting this approach, manufacturers can create leaner and more agile operations that are better equipped to thrive in today’s competitive landscape.

Get in Touch

If your organization is ready to unlock the untapped potential of its indirect functions and drive transformative efficiency, we’re here to help. Whether you’re looking to streamline processes, eliminate redundancies, or leverage digital tools for smarter operations, our expertise can guide you every step of the way.